Carbon dioxide (CO2) removed from natural gas is often treated as a waste gas and simply vented to the atmosphere. If the waste gas contains significant amounts of hydrocarbons or other impurities, it must usually be treated in a flare or thermal oxidizer before being vented further adding to the operating cost of the natural gas treatment. This is a particular concern for small-scale natural gas treatment systems using membranes or pressure swing adsorption (PSA) for CO2 removal.

SulfaTrap™-R5 sorbent can be used to recover food-grade carbon dioxide from the waste gas from small-scale natural gas treating systems. Our compact, modular system integrates between the membrane or PSA and the flare or thermal oxidizer and reduces the volume of waste gas to be incinerated, thereby reducing operating costs while producing a food-grade CO2 product. The small scale of our system is advantageous for supplying local market needs for food-grade CO2 whereas an industrial-scale plant would overwhelm the local demand.

Our technology

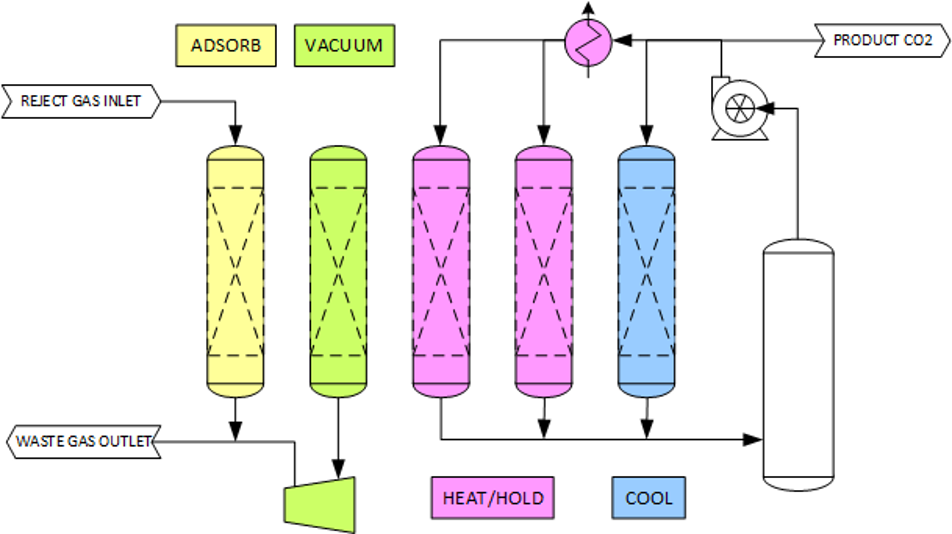

SulfaTrap uses a combined pressure and temperature swing to produce food-grade carbon dioxide. The process is illustrated in the diagram below.

FEATURES

- Regenerable sorbent is formulated for long life and fewer sorbent replacements

- Non-toxic, non-flammable and non-pyrophoric; safe to handle and easily disposed

- Highly tolerant to air, water vapor and carbon dioxide

Figure 1. Generic process scheme for the food-grade CO2 production system

The SulfaTrap™-R5 sorbent is housed in five vessels; one vessel operates in adsorption mode, while the other four vessels are being regenerated. During the adsorption cycle, carbon dioxide is removed from the CO2-rich reject stream from an upstream CO2 removal system. The CO2-free gas from the adsorption vessel will be routed to a flare or thermal oxidizer for disposal. The adsorbed CO2 is removed from the sorbent during the regeneration phase for each vessel. The food-grade CO2 product is the regeneration off-gas.

Sorbent regeneration is carried out by first evacuating the sorbent vessel to remove the untreated feed gas from the free volume in the sorbent vessel. The adsorbed CO2 is released by heating the sorbent with a sweep gas stream of the clean CO2 product. The sweep gas and desorbed CO2 flows through an outlet accumulator to buffer swings in CO2 product delivery temperature and pressure. Once the vessel is fully regenerated, it is placed into service for another adsorb/desorb cycle. The excess CO2 product is removed from the outlet accumulator on pressure control.

PRODUCT APPLICATION

SulfaTrap™-R5 Carbon dioxide removal sorbent