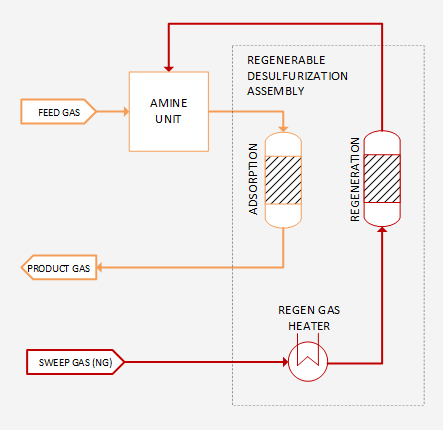

In sour gas sweetening applications with large sulfur loadings, amine units are traditionally used for effective bulk sulfur removal. However, most solvents leave behind organic sulfur species such as mercaptans and COS. In some cases, the prevalence of these secondary compounds can cause the treated gas to exceed pipeline sulfur specifications, and may require further polishing. SulfaTrap™ regenerable sorbents demonstrate a high removal efficiency for these compounds, offering an economic solution for the final polishing step to < 0.1 ppm total sulfur.

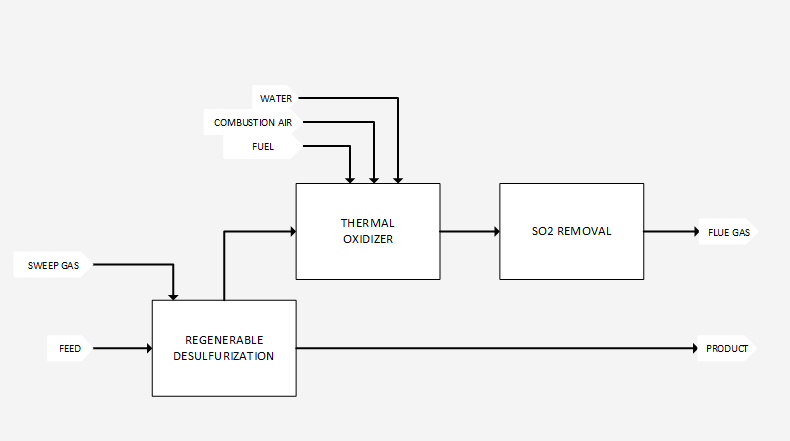

SulfaTrap™ sorbent is regenerated via a mild temperature swing using a clean sweep gas stream, and the sulfur compounds adsorbed onto the sorbent are released in the form they were adsorbed (e.g., ethyl mercaptan adsorbed onto the sorbent is released as ethyl mercaptan during the regeneration step). This concentrated mixture of sulfur-laden sweep gas must be further treated to provide a permanent sink for the sulfur compounds.

- Mercaptans may be re-treated in the Acid Gas Removal Unit

- Organic Sulfur may be converted to Sulfur Dioxide (SO2) for consequent removal of SO2 using dry-solid or wet scrubbing

FEATURES

- High selectivity to all sulfur species

- High removal efficiency - sulfur concentration is reduced to less than 0.1 ppmv

- High capacity - SulfaTrap™-R5 and SulfaTrap™-R2 achieve up to 20% capacity in regenerable operation

- Regenerable operation - nitrogen, natural gas, or clean process gas may be used for regeneration

PRODUCT APPLICATION

- SulfaTrap™-R2 Regenerable desulfurization sorbent

- SulfaTrap™-R5 Regenerable desulfurization sorbent