A new adsorbent-based separation system is being developed for selective removal of N2 (and potentially carbon dioxide, CO2) from natural gas. The adsorption process is driven by a pressure swing cycle (PSA) which delivers a high purity hydrocarbon stream that meets sale gas BTU requirements, and a nitrogen-rich reject stream that can either be flared or re-compressed for further utilization. The technology is based on a proprietary molecular sieve material with highly favorable pore size distribution to allow the removal of N2 (and CO2) over methane (CH4) based on size selection.

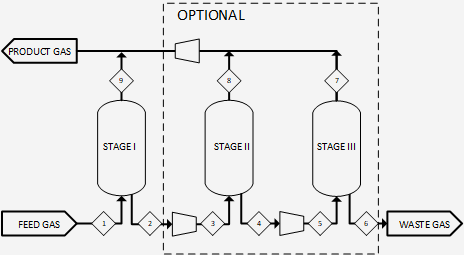

The new multi-stage PSA system can effectively reduce the total N2 content of the gas to less than 3% vol. while achieving hydrocarbon recovery efficiency in the 70-90% range. The operational cost and capital requirement estimated for the new system indicates the new technology compares very favorably against traditional cryogenic separation systems and the published results for state-of-the-art membrane and adsorbent-based N2 rejection systems.

FEATURES

- Kinetic selectivity toward nitrogen

- Sorbent capacity does not degrade in the presence of C2-C4

- Single stage treatment achieves < 3% N2 and 70% methane recovery with zero compression costs

- Installed reactivation system allows contaminated sorbent beds (sorbent performance may degrade slowly over time in the presence of moisture) to be reactivated without operational interruption

- Operational cost is low compared to state-of-the-art separation technologies such as cryogenic, membrane, and carbon molecular sieve

PRODUCT APPLICATION

- SulfaTrap™-NRU Nitrogen rejection sorbent